All Activity

- Past hour

- Yesterday

-

TK-70384 Requesting ANH STUNT EIB Status (WTF)

Slouch replied to Slouch's topic in Request Expert Infantry Status

Thanks so much! I just popped the Han Snap pic in. I moved it from the previous position, so it's more square in the corner. I hadn't seen the internal of the thigh ammo on the checklist - it just said L & R and I thought that meant external, but I'll grab a pic when I'm home - Cheers! -

Sly11 started following New - Bakersfield CA

-

Welcome to FISD Steve! Looks like you have things well underway, we look forward to seeing photos of you fully kitted up.

-

TK-70384 Requesting ANH STUNT EIB Status (WTF)

gmrhodes13 replied to Slouch's topic in Request Expert Infantry Status

Good luck with your application trooper You may want t have a look through this checklist for any missing images (Han snap closeup), also inside connection thigh ammo strip -

Hello and welcome to the forum, good luck with the research, this thread can be a great assistance to the first time builder

-

No not specific to Luke and Han they are both part of the Hero CRL, optional items which had been worn by Luke are the grappling box/hook and comlink Haven't seen a maker of the grappling hook for a while but there are print files here Or you could scratch build like I did

-

[70+] TK-61490 "TheRascalKing"'s Troop Log

TheRascalKing replied to TheRascalKing's topic in Field Training Exercises

95. Live Like JoJo Walk - San Clemente, CA - Sun. 10/20/24 (ANH-S #65, FTE #74) And a silly one for fun: -

[70+] TK-61490 "TheRascalKing"'s Troop Log

TheRascalKing replied to TheRascalKing's topic in Field Training Exercises

*WRANGLED - The Bradley Rofer Baseball Tournament - Coto De Caza, CA - Fri 10/18/24 Wrangled this one with my son so that my wife (the Jawa) could sneak a troop in before the census closes - it was her first since we had our son late last year and was a great event to support! -

alerama7 joined the community

-

Hi folks, I’m thinking of converting my original ANH Hero TK into a Luke TK. I’m a rather short Stormtrooper so kind of makes sense. Is there a CRL for this? I can’t see anything on the databank. Does anyone know where I can purchase a decent grappling hook? Thanks, Tim

-

TLJ vs TFA accuracy requirements

ZombieGraves replied to ZombieGraves's topic in Assembly, Mods, and Painting

That's very comprehensive, and super helpful, thank you very much! -

Hello. I'm just getting started down this rabbit hole. I have been interested in a Stormtrooper (ANH) suit for years but have never been able to get to the finish line with one. I've 3d printed a helmet and it came out ok but I just wasn't really satisfied with the finish and didn't really like the 3D printable armor I was able to find online. So, after years of wanting... I finally reached out to a couple people, one who is 501st and got some more direction and advice. I'm happy to say that I just commissioned the build of a Stormtrooper Stunt Pro Built Suit (ANH) through RS Prop Masters. I'm currently working on all the required measurements they need and will have that info to them by the end of day. RS Prop Masters is advising a 12 week lead time for the suit so, I plan on using the time to research more about the sound stuff (icomm/akers/etc) so I can get all of my ducks in a row for when the suit arrives from the UK. I have a friend that built an R2D2 years ago and he goes to a lot of charity type stuff with it and I've always thought it would be fun to go to some of those events with him, so that is what I'm interested in so far. I'm still exploring the 501st forums and trying to get a better feel for everything. Once I get my suit from RS Prop Masters I think I will be filling out an application for the 501st and go through that process. I'm pretty excited and anxious to get my suit and plan on getting a mannequin so I can display the suit when I'm not using it.

-

Stingray joined the community

-

Versatyre joined the community

-

Hi Team. Please find below my request to be approved to EIB for my ANH Stunt kit from WTF. Name: Chris TK ID: TK 70384 Forum Name: Slouch Garrison: Knightfall Garrison (Melbourne, Australia) Armor: WTF Helmet: WTF S Trim: WTF Blaster: Bounty Hunter Armory Height: 186cm Weight: 88Kg Boots: TK Boots Belt: Made Myself Rubber Hand Plates: N/A Gloves: Rubber chemical Neck Seal: Darman's Props (Etsy) Holster: Made Myself Lenses: WTF Helmet Fans: Imperial Fans Electronics: N/A Dropbox Backs: WTF Decals: Dave M - Trooperbay Undersuit: Kmart/Amazon https://www.501st.com/forum/memberlist.php?mode=viewprofile&u=25803 Full Body: Front Back - I swear the bridges are even - I was just standing weird! LHS RHS LHS Arm raised RHS Arm raised Action Shot Armor Details: Ab plates Cod & Posterior Plate connections Interior Strapping Wrist Openings Split Rivet Side Connection Han Snap Sniper Knee Plate Thigh Ammo Belt Helmet Details: Front Left Right Back Lenses Accessories: Neck Seal TD Holster Attachment ABS / Canvas Belt Boots Rubber Gloves Blaster Details: Left Side Right Side D-Ring A few things to point out: I have quite broad shoulders and have done everything I can to get the shoulder bells as close as possible to my chest piece. It's also causing me grief with my shoulder bridges and I can't trim the rear tabs without it looking too short, unfortunately. I took the previous suggestion of doubling over the white elastic straps, but my physical build means I either have weird sitting bells OR slightly exposed elastic in certain poses. Tried both and the latter looks far cleaner. If I look a little wonky in the shots, it's more to do with my bad back than the strapping/alignment (my user name is Slouch ). Also a bit of pressure from my impatient photographer (wife) and didn't want to press my luck for a reshoot after scrutinizing the photos myself. I do plan to move my ears back to align better with the rear traps, but am awaiting replacements. Hopefully current positioning will suffice for Level 2 approval. Also awaiting replacement hovi tips, but hopefully these arrive by the time this is processed and I'll update the pic. If there's any other details/photos required, please let me know. Many thanks - Chris

-

TLJ vs TFA accuracy requirements

gmrhodes13 replied to ZombieGraves's topic in Assembly, Mods, and Painting

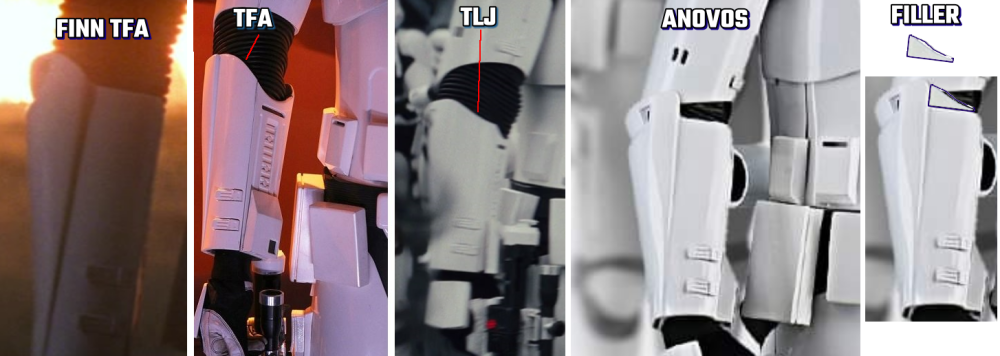

Even with a TLJ helmet some of the armor does need work to be approved, joining and filler some areas is needed, either ABS paste sand and polish or filler and paint. Differences between the two are Helmet, lots of differences, clips, shape, teeth, frown, and of course the shape/details of the clips as well as extra gap around the clip in TLJ/TROS version TFA Anovos (albeit there was the premier fiberglass and at least 2 plastic versions so they may vary) TLJ screen used helmet, note the gap around the clip and shape/details compared to TFA Denuo Novo TLJ has similar clips and no gaps like the TFA Anovos so it's not very screen accurate. Justin @TheRascalKing offers 3D files for helmet clips, you would have to change sizing to suit your helmet Cod Forearms Anovos/Denuo Novo have a step, similar to Finn but still not quite right, many add a filler piece of ABS and add ABS paste, sand and polish, Justin has a nice DN build here Detonator TFA TLJ has a separate pipe as well as cut out on the housing The TFA TDS were solid resin and weighed 1.5kgs. For TLJ they completely redesigned the TD, cut-out the apertures and created a lightweight insert. There are also some difference in the blasters, more info in this thread At the end of the day it's all down to your GML (garrison membership liaison) and what he/she/they will approve at base level, some are stricter than others, some may miss small details, detachment only looks after the higher level approvals L2 and L3, more detail info on higher levels you can contact the @Deployment Officer Team and also check out the CRL's (costume reference library) TK - Stormtrooper: The Force Awakens TK - Stormtrooper: The Last Jedi First Order Battle Group for everything FOTK related Locating your local 501st garrison https://www.501st.com/maps/ -

ZombieGraves started following TLJ vs TFA accuracy requirements

-

Hi troopers, I'm in the middle of my first armor build right now and I've got a couple of questions. I'm one of those unfortunate folks who ordered a helm and TFA FOTK build kit from Anovos way back in 2016. I received my TFA bucket in 2016, and only just now received the armor kit from Denuo Novo. Here's the thing though, the 2016 Anovos bucket is TFA, which is different than the TLJ or ROS helms. It's got the infamous round clips, no teeth, etc. However, the kit that I received isn't TFA, it's TLJ/ROS; it's got square clips, the newer cod, etc. Obviously, I'll have to go find a new cod piece, but what about the clips? Would I be able to get certification with square clips and a TFA bucket? I could just find a TLJ/ROS bucket and use the armor as is, but that's pretty expensive when I've already got a serviceable helmet that looks almost right. Then again, I've got a resin printer and could make a set of round clips. Aside from the cod and the clips, are there any other differences between TFA and TLJ/ROS body armor that I should be aware of? What would you guys choose to do here?

-

113. 09-28-2024, Saturday, Jaxson's Train of Hope Fundraiser Total TK Troops: 113 Total Legion Troops: 133

- 1 reply

-

- 1

-

-

VaderDave changed their profile photo

-

[15] TK - 11198 trooper log (social media consent)

camroc13 replied to camroc13's topic in Field Training Exercises

James Arnold Taylor signing! Sent from my iPhone using Tapatalk -

[15] TK - 11198 trooper log (social media consent)

camroc13 replied to camroc13's topic in Field Training Exercises

14. Light the night! Sent from my iPhone using Tapatalk -

[15] TK - 11198 trooper log (social media consent)

camroc13 replied to camroc13's topic in Field Training Exercises

13. big Texas Comic comic con 2024 Sent from my iPhone using Tapatalk - Last week

-

Machinaww joined the community

-

Electroprod References TROS The electroprod was an electrical melee weapon. The DX-90 electroprod[2] was carried by the electroprod troopers, specialized stormtroopers of the First Order, who operated during the First Order's war against the Resistance 3d Files by 9142PropsAndArmory (FREE) https://www.thingiverse.com/thing:4099843 Glen TK85421 gmrhodes13 build https://www.whitearmor.net/forum/topic/48855-electroprod-version-1/

-

51. Al Sigl Community Walkabout, 20 October 2024 And Troop #75 overall With @tdurden and TKTommy.

-

The Stormtrooper Hall of Fame

BAZINGA replied to Holnave (evan_loh)'s topic in Field Training Exercises

Congrats! Bart -

Welcome to the FISD. Good luck with the Phasma build. We used to have one in our Garrison and it really was a cool costume to see and troop with.

-

Albums

-

Boots - Return of the Jedi

- By Darth Aloha,

- 0

- 7

-

Space Pack - ANH

- By gmrhodes13,

- 0

- 0

- 7

-

From the sets of Return Of The Jedi

- By Nairy,

- 0

- 28

-

From the sets of The Empire Strikes Back

- By Nairy,

- 0

- 18

-

From the sets of A New Hope

- By Nairy,

- 0

- 133

-