-

Posts

192 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Everything posted by bishopdonmiguel

-

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

Troop 016 -- 2019/12/19 -- Rise Of Skywalker Opening Night in Kansas City, MO -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con't): @gmrhodes13 pointed out that there should be a indentation on the right side of the TD. Time to fix that. I decided on a 2-1/8" inner circle and measured the outer circle to match that of the TD. Used a vinyl stencil to cut a ring from scrap ABS. You might notice that the scrap was just a tad undersized on 2 edges but this will get filled with putty. Using the inner vinyl circle as a mask, I removed the primer to expose the raw ABS on the TD. This will allow for a good bond with CA glue. Fill, sand, prime and done. Hope this passes muster. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Small update. My FOTK Boots from Imperial Boots arrived. Nice. -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

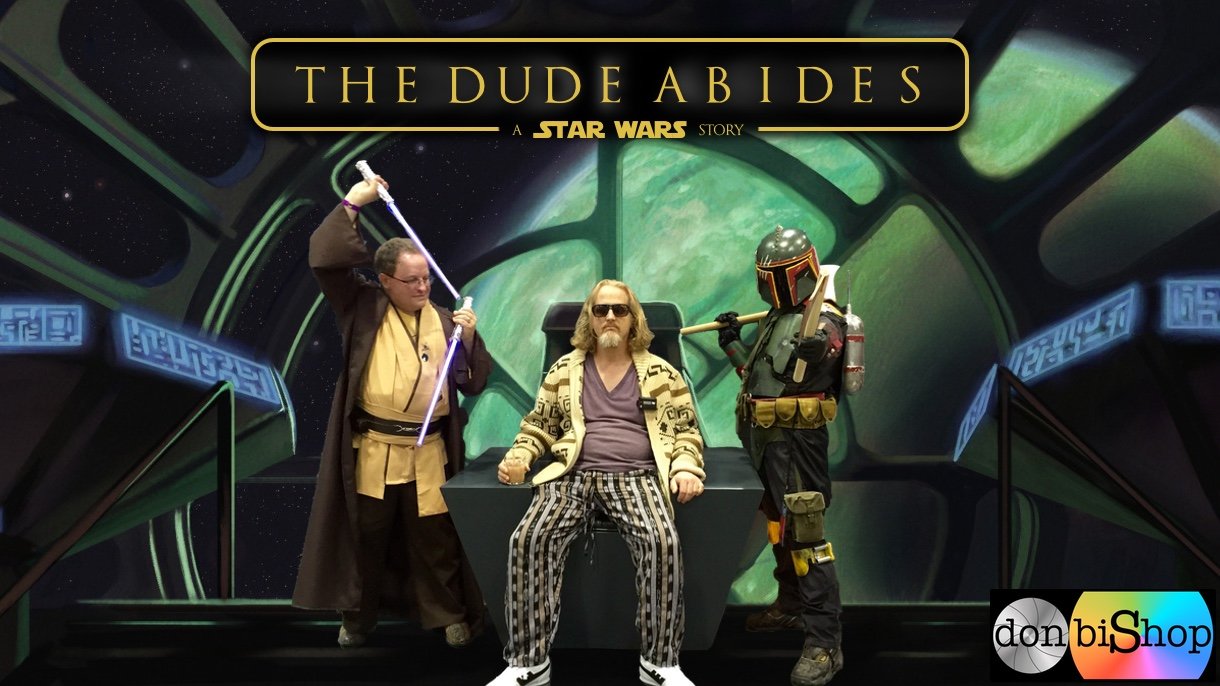

Another photoshop interlude, this one featuring my Squad Leader. -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

“He’s a mean one, TK Grinch.” TK 21393 Photo by Chuck Mason, posted with permission -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

Troop 015 -- 2019/12/14 -- Shadow Buddies Fantasy Flight in Kansas City, MO -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

Troop 014 -- 2019/12/12 -- Turner Community Library Holiday Party in Kansas City, KS -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Okay, this is weird. On a browser, link properly displays photo. On Tapatalk, link resolves to some random thread. Seems like a bug on the Tapatalk side. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Yes. The link is supposed to take you to an abdomen photo. Maybe I screwed that up. Sorry. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Question: Anyone know the dimensions of the small abdomen boxes? I’m guessing 1.5” x 2.75” (38mm x 70mm). -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Forearms: I’m not satisfied with the soft corners in the forearm boxes. I tried sharpening the edges but the material is getting too thin so I’m building covers. They are a bit too wide I think but I can’t do much about that without a complete restoration and that seems a bit overkill even for me. As part of the modification, I’m creating bigger recesses. Question: Another thread recommends 7/8” x 7/8” decals to fill these boxes. Is that the correct size? -

December FISD Newsletter 2019

bishopdonmiguel replied to gmrhodes13's topic in The Newsletter Archive

Heehee. I’ll tell you what, that was a day for the books. I had just seated myself for a quick bite in the mess hall. It was French Toast Day and everyone knows Imperial French Toast is the Best French Toast. So just as I’m pouring on a thick layer of maple syrup, the Sup yells over the comm to report immediately to Docking Control Room 327. I grab my gear, rush over there and had a bit of trouble opening the door. While the Sup worked on that, my mind kept drifting back to that delicious French Toast. Then BAM! The door opens and I am ripped away from my culinary daydreams. I guess I instinctively burst into the room and... bonk. Thankfully the Sup didn’t notice and we spent the rest of the afternoon chasing a group of stowaways around the Station and trading laser fire. Not a great day and I never did get back to that French Toast. p.s. you are correct, the movie trooper sustained no damage but there’s nothing wrong with imagining “what if?” -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Missed that. Thanks for the intel. Will fix. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con’t): Applied some primer so I could see where I needed to follow up with spot filler. Given how this started out, I’m happy with the result. Question: Did I overlook any details that would hold up approval? -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con’t): Once again, I turn to my vinyl cutter for a stencil. This time to create the indentation on the TD. A shallow grinding with the Dremel followed by some sanding to clean up. If only the rest of the TD build was this easy. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con’t): I’ll spare you all the small iterative changes over several hours of work. After getting the shape of the tube nearly finished, I mounted the tube to the back plate using CA glue and (6) pull rivets with washers. A hole was cut in the back to facilitate installation and then filled with expanding foam to fill the void and help keep the tube as rigid as possible. If anyone wants pictures of that, shout. More filling, more sanding and I’m reasonably happy with the result. BUT I noticed the piece shown in the CRL has detail on the bottom this one doesn’t have. Basically, the ridge lines of the back plate continue down behind and below the TD. Solved this by affixing a couple pieces of scrap glued together, shaped like the ridge line and affixed to the bottom. The major work on this is now done but I will need to add a groove on the top and eventually finalize the thickness of the back plate. I will do that later when I get the armor ready to wear for fitting. Glad to have this part behind me. I think the assembly of the TD could be simplified greatly by a redesign. But if many builders simply jump to using the 3D print, might not be any incentive for 850 Armor Works to make a change here. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Hmmmm. I like the idea of anything that helps clean up PLA. Not heard of MC. Any safety issues with this stuff? -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con’t): The shape gets some refinement with another application of body filler. But the ends are just awful. They need a more circular shape and the inner and outer cylinders need to be better aligned. This will be accomplished with much filling and sanding. I created a few “tools” on the 3D printer to help with this. Basically a couple of rings to use as guidelines for the left side and a “plug” for sanding the depression on the right side. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

Thermal Detonator (con’t): My solution is to extend the length of the right side cap so it can fit inside the tube. I will patch the voids with body filler. I also took care to extend the cap shim material beyond the end so I can create an indentation for accuracy. Once assembled and a preliminary filler is applied, I can see I have SO MUCH MORE WORK LEFT TO DO on this piece. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

I am sending out my forearm STL file to have someone print on SLA. From that I’ll make a mold and casts. Cleaning up that PLA looked like more effort than I wanted to invest. While I wait for that to come back, time to address the elephant in the room... the Thermal Detonator. Honestly, this thing is a just mess. 850 Armor Works does provide a 3D file for skipping this part of the build and printing a TD. I’m not a huge fan of PLA parts so I’m taking the difficult path. The assembly isn’t intuitive and there may (probably) have been a better way to approach this. But I gave it my all. Thermal Detonator: I laid out the parts as best as I could determine. The left side obviously fits into the tube but I’m not sure how the right side is supposed to work. I have no idea why the tube has those odd cutouts. After cutting the edges straight, I assembled the tube using internal cover strips and CA glue. Couple of magnet pairs help hold thing together. Now that the tube is assembled, the dilemma for the right side cap is better illustrated. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

VERY interesting! Thank you for that insight. Love to hear these little details. -

Bishop's 850 Armor Works FOTK Build

bishopdonmiguel replied to bishopdonmiguel's topic in TFA Build Threads

I think I have stated this previously, but I’m holding off assembling any limbs until I receive my gaskets. The thickness is an unknown issue and I made sizing mistakes in my OTTK build. In the meantime, I’m working on some other things like the forearm details. The kit includes a resin cast of the inset but to my eye it is not accurate and cleaning it up would require too much work. So I designed a 3D model of the panel that fits this kit and printed. I’ll be molding and casting this in semi-rigid resin. Question: Does this look okay or are there changes I should make? Don’t want to spend time cleaning it up for molding if there is a design element I’ve overlooked. -

December FISD Newsletter 2019

bishopdonmiguel replied to gmrhodes13's topic in The Newsletter Archive

Very kind of you to say. Thank you. I do these monthly subject to pics available from our group. The November 2019 edition is now in my Troop Log. -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

Troop 013 -- 2019/12/08 -- Mid-America Chapter Leukemia & Lymphoma Society in Kansas City, KS -

[50] TK-21393 Troop Log

bishopdonmiguel replied to bishopdonmiguel's topic in Field Training Exercises

Troop 012 -- 2019/12/08 -- Jingle Bell Run For Arthritis in Lenexa, KS