-

Posts

1,016 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Posts posted by charlesnarles

-

-

I use Photobucket.com (not the app).

You'll get better at identifying extra plastic (flashing) as your projects branch out. I made the mistake of assuming some details were erroneously present when they were actually integral to the functional design of the original cast part. If you have any doubt, check a reference photo before making changes (but small mistakes are easily fixed, as others say).

Good luck and keep it up

-

I like it, Bill! Haven't lurked much in the dlt-19 section but it's great to know it's such an easy mod. eBay, huh...ðŸ˜

-

Beautiful. I'm convinced Disney had this in mind from the drawing board, it's too perfect! The DVH bolt I have is already hollowed out, so you've quelled my fears about ruining it by trying this. Careful not to snap their crappy wires😉

-

1

1

-

-

I sacrificed a EE3 (Boba's) and put its guts into an E11 really easily. The parts are similar enough to fit inside each other without too much trouble. I also replaced the LED with a bigger one, to ensure the EE3's barrel reflector plastic would catch enough light to not need a muzzle bulb. Here's the link to my old project I still need to finish (or sell):

http://www.whitearmor.net/forum/topic/28274-hasbrodroopydoos-e-11-build/

-

Can't decide if I should have wires come out the counter, probably not. It's just staring me in the face and they'd be functional but I'm also worried about their integrity.

You can see the internal metal, plastic and wires through the front vents, which will be neat.

I should mention how thin the walls of the resin half have to be to fit the counter. My eagle is translucent, for example. Idk how I didn't dremel through!

-

It has screw-down connectors and counts circuit closures of whatever you attach the other end of the wires to. I think it'll work if I put them on the "trigger" connectors, or maybe the fire select switch so it won't count if the safety is on😎

-

No, it's a 2014 DVH 😉 sorry to get your hopes up

After seeing Allan1313 fit Disney guts into a PP bolt, I remembered that T-Jay's kit comes with a Doopydoo's recess-sized "bolt" which might just be the perfect size for the Dsny board

-

2

2

-

-

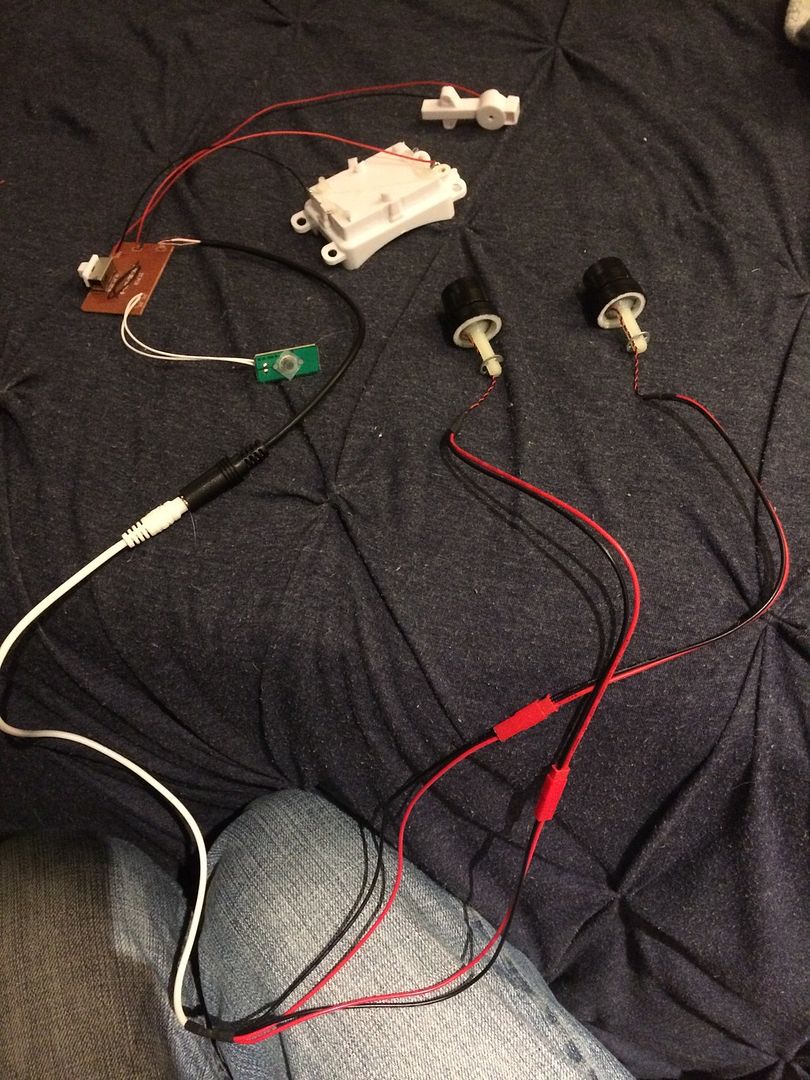

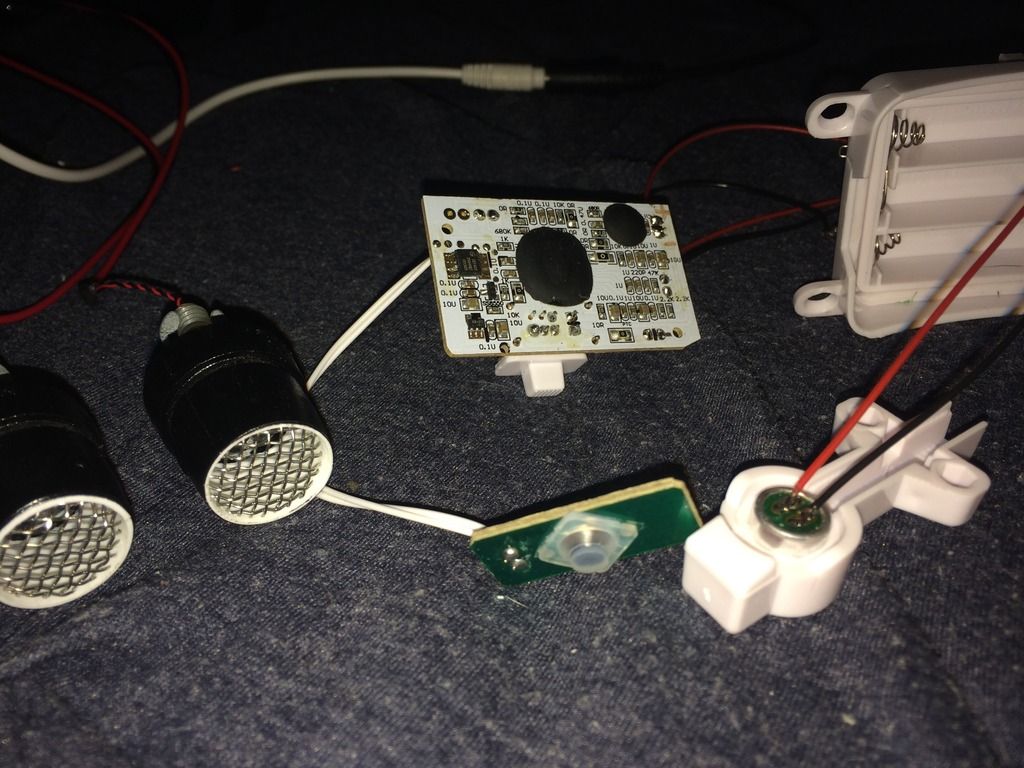

Got the doopy Hasbro convert counter cut and hollowed. Everything fits nicely with room for the wires to be attached:

-------------

-

1

1

-

-

My plan is to find a small metal pipe to fit the stock hinges onto. Should work just fine.

And it did indeed come with a charging handle, it had fallen out of the bag in transit. They explained how sealed ziplock baggies trap air so pieces have room to fly around and break. Nothing came broken so I guess it works.

Today I washed and painted my bolt and scope... It wasn't pretty. The antique brass paint did a big raspberry, spewing trapped propellant inside glittery paint bubbles and leaving the least even coat I've ever done. It was literally dripping in areas and bare in others, so I washed as much off as I could with water. Here's what I ended up with:

Not exactly what I was hoping for, but maybe I can sand or strip it and try again (I do have 6 of the darned cans). Notice the fingerprints and general globbiness. The lettering looks pretty good under a more lightly coated area tho:

Hopefully it's still salvageable, and they're cheap if not 😅

The bolt was easier, apart from the can not wanting to spray its aged steel paint at first. It was a lot less spitty and I did a super light coat. I like the darker silver color and less glittery appearance than the brass. Again, the lettering shows up, along with all the details. Looks pretty good in comparison lol:

-

1

1

-

-

Turns out it's illegal to buy 10+ bullet magazines in CA without a peace officer permit. So never mind, you'd think they'd sell pre-cut ones...ðŸ˜

-

Glad to have you. If you're reeaally short you could see if a child/reduced-size suit would, well, suit you better than 1:1. Legacy armor is very cool too, good luck deciding 😎

-

1

1

-

-

It's normal, give them a few more days. Rebel Legion takes even longer😋 Hope to see you at some armor parties. There are at least a handful of prospective troopers relatively nearby, myself included. Welcome!

-

I overestimated. I can kiss the mic so it's probably 1/2" or 3/8" away. I wasn't consciously enunciating the whole video but it's much clearer when I do. The little round mic has that white plastic cover which must help with pops but idk if its tiny hole is the cause. I tried speaking really softly and it picked it up, I think my issue was being tired more than the mic being crummy 😅

-

Sure. I have a big skull and it's an ATA, so there's an inch or less of space. Still have to use an outside voice for the mic to pick it up, but that's solved by soldering on another female Jack and using a better one. A throat mic with VOX would be ideal 😎

-

-

-

I'll do one of the changer with fans and everything going soon. And yes there's a nice unobtrusive click/burst at the end

-

Man, how do you get to be an extra on these things?

Is the answer nepotism? 😅

-

Welcome, Kitsten! Most armor takes the maker a month or so to pull (if you're lucky lol), so you should have enough time to save up. With your discerning taste (evidenced by your dog breeds/namesðŸ‘), I'm sure you'll do fine once you start your build. Just follow the CRL and look/ask for help beyond that. Glad to have you with us!

-

1

1

-

-

So jealous of your debazed mag well ðŸ‘

-

1

1

-

-

High-tech and won't wear out. Keep it up, brother!ðŸ‘

-

1

1

-

-

Huge thermal detonators? Maybe not. (They look unhappy to see a drone snapping pics to leak)

-

2

2

-

-

You won't be disappointed, they're comfy and look great. Only real discrepancy is the wider shape of the heel strip, but that's fairly negligible IMO

-

1

1

-

-

Good eye noticing the nozzle evolution, it's really improved even with the infamous hex blobs. That's how they all come btw. Yours doesn't look softer than mine from very recently too. Unless I just can't tell!

S&T(airsoft) Sterling L2A1 to E11 "build" thread

in ANH BlasTech E11

Posted

Since the real one doesn't fit, I'll use it on my Doopydoo's. Still deciding whether to try to dremel the steel into the right shape or try to fit a resin one instead. The S&T cap is very thick where id be removing material, so I feel like it can withstand the change. I'm really interested in seeing their E11 edition with (apparently) more accurate cap and handle