-

Posts

253 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Posts posted by husky68

-

-

On 3/17/2019 at 7:33 AM, gmrhodes13 said:

Also at this stage have a think if you would like to keep anything inside the tube, having a removable end cap can be handy, I added an angle piece of abs to the insides of the caps, glued elastic to one, then on the other end added Velcro to the elastic and plastic angle, can now pull the cap off and remove the elastic via the Velcro.

Just somewhere to keep items, trading cards, wrist bands, working with children card (we need them locally) that sort of thing.

This is the kind of reply I was hoping for earlier when I pondered storage. This looks great but the elastic might take up some storage space or get in the way of larger items. The caps are already a super tight fit and I have read some hot bath them to relax the plastic and avoid stress on the plastic. My tube has thick walls so I've got room to sand them down for a smoother fit. Might consider a locking ring or something with magnets.

-

1

1

-

-

I tried taping off the frown, maybe using more tape then needed but hopefully will do the trick. I also tried taping the vodocoder but found it to be rather tricky as the ridges are very faint. Added some pencil shading but still not sure how to get the tape to follow the curves that I want. Taking any suggestions on how to get it taped up clean.

-

Belt position looks good but the thigh strips need to be trimmed.

Cookie box from Tokyo Disneyland.

-

1

1

-

-

Took the week off and was kept busy with life. Took out the forearms tonight and was thinking of filling the trenchs when I made a realization. The armor is 1mm thick and the ABS strips are 2mm. So this presents an issue for filling the trenches. Also it is likely I will have to do trenches for the shins and maybe the thighs so this will be a continuing issue. Maybe making some abs paste is a possible solution.

Anyway, after deciding I needed some progress so I sanded down the edges of my TD tube and taped it off for future rattle can sparying. The center tape is smaller than the panel so there is overlap in case I reduce the size later. Maybe the glue will work the same on the paint but decided to leave some original material in case.

-

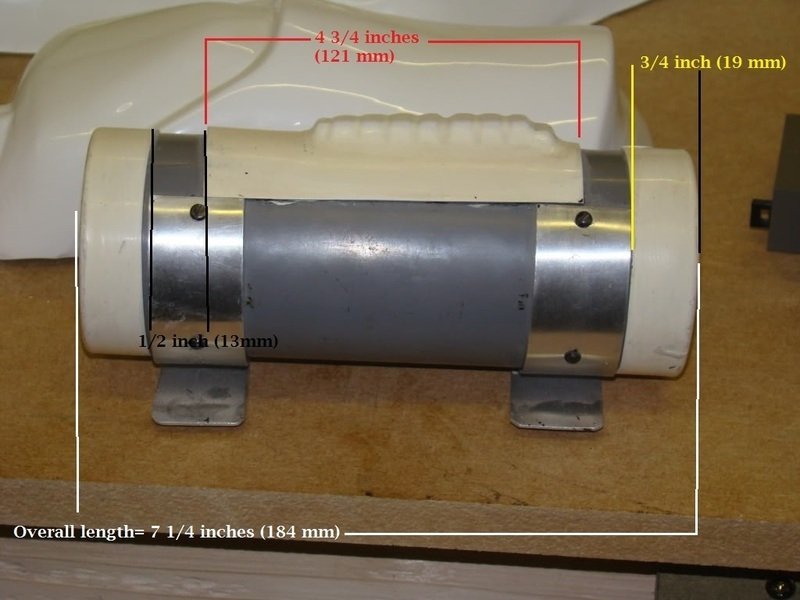

Attended my second armor party in Tokyo and concentrated on my TD. The CRL being 190.5mm and the reference image being 184mm, I've decided to go for CRL measurements with aspects close to the reference image. So I cut the end caps and used a belt sander to get them to 20mm ( image makes them look slightly different but they are identical.)

The tube is black which have already purchased rattle can of grey to paint. The diameter is a perfect tight friction fit without glue and matches the CRL. The length was a bit over given the caps add an extra 10mm each so I also gave this a trim. Given some final fine tuning I should be able to get the CRL length of 190.5mm

I'm always considering novel options and was wondering if anyone tried using the TD as a storage container? With the exception of the screws poking inside it is basically a hollow tube with end caps that could be removable. Even if it just held a repair kit inside. Also magnets could be glued inside to hold it to the armor/belt to reduce chance of it falling off or stolen by those tricky jawas?

-

1

1

-

-

On 3/9/2019 at 4:24 AM, MakeNoiseMan said:

Sorry to hear that the glue is still not holding, though.

Thanks, I think it is from earlier gluing where I didn't rough it up enough. Now I scratch cross pattern into the strips hoping to end the cycle of glue.

On 3/9/2019 at 4:24 AM, MakeNoiseMan said:If you're shooting for L3 they may just ask you to trim off the itty-bit of return edge still left where the track of recesses is.

I'm trying not to set my expectations on L3 but trying to build to the best of my ability which may one day get me to L3. I've seen other AP kits need to trim that last bit which is super close to the ridge. I've wondered about instead of cutting to try bending it up, but that is getting ahead of my initial goal of just making wearable armor that will make basic.

-

The battle with the forearms continues with inner strips in place. The new V trenches in the back keep the wrist smaller and top wider but strips are still separating in small areas along the inner strips. One last attempt to glue them down before I start hot bath reshaping. If they lift again will tear them off and start over.

-

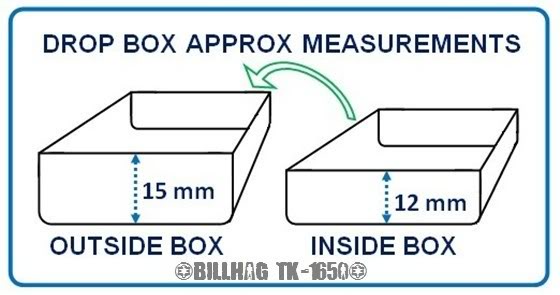

Just want to check on how strict measurements are for drop boxes. Sounds like there is some variety on this, some use them for storage, and mine are big enough that I should trim them down. Just wondering how much, suggestion below in image but seems others have slimmer ones.

Also for the TD, the CRL mentions 190.5mm while image below suggested 184mm?

I might just be tumbling down the rabbit hole.

-

With some sunlight on the patio I was able to get in the well ventilated space and use the dichloro methane to join the two first major pieces. I also brushed down the entire joined piece making it a bit smoother.

I'll give it some time to really set before moving forward. Also smoothed the next piece of the barrel to be connected. The bolt slides too far into the barrel, past the charging handle hole if it is not in place, so I will need to put something inside to stop it at the right spot. Once this is done I will complete the barrel and continue with the build.

Also in my spare parts I have a muzzle tip and Hengstler counter which I will likely use on the Disney blaster.

-

1

1

-

-

11 minutes ago, BigCara said:

Snap time

Don't you mean "hammer time"

-

Went to Tokyo Disneyland and picked up some new swag

The popcorn bucket is added to the already purchased R2-D2 and BB-8 buckets. The blaster has 2 light and sound modes, which is fun to play with, for only 2,500yen ( about $23USD). There is build logs existing showing some nice mod work which I might follow to make this a backup and more kid-friendly blaster for non-canon events. Will still focus on accuracy for my 3D printed blaster. I even have some spare parts that might find a use for this blaster.

-

2

2

-

-

32 minutes ago, Digz Graavz said:

try roughing up each surface with an aggressive sandpaper before gluing to help give it something to stick to.

I'll step up the sandpaper before gluing.

28 minutes ago, wook1138 said:let the glue set for at least 24 hours - 48 ideally.

I'll wait the full 48 hours.

23 minutes ago, Digz Graavz said:You could also try adding some CA to the inner strips when you glue them to get a bond.

This might be last resort as I have heard CA can be more unforgiving of mistakes and permanent.

-

The forearms are really driving me crazy and it feels like I can't make any progress.

Shape of forearms is opposite of what I need. Pieces don't naturally fit together so glue is not holding. Failed attempts at hot bath because no pot will fit these forearm pieces together with clamps, pouring water over the pieces even less effective. Can't finish inner strips without them pulled away from one side or the other. Even had a complete failure with strip letting go of one side and back to two pieces.

The other forearm with both inner strips is pulling away from the strips on both sides.

I'm going to try to finish the inner strips then fill sink with boiling water and see what I can do about shape for both fitting my arms and holding the strips.

-

Two rings become one. Unable to pull them apart, stronger together than they were individually. Appears dichloro will make a fine chemical weld for the blaster.

-

2

2

-

-

Some additional work this weekend but mostly just sorting things out. First one of my biceps is finished, except for trimming of strip, and the other bicep has one side done. I am holding off completing the other bicep in case some later cast off cut of ABS fits.

Next I also put a strip on the forearms with a gap of about 4mm for both forearm front sides. One has finished glue setting and the other should be set tonight. The main issue is my forearms are both large and wide in the opposite curve of the armor. Additional size with trench only gives more space in the direction that I am not lacking. So hoping some hot bathing and reshaping will both make the fit better and reduce the trench needed. Basically I need to change the horizontal oval to a vertical oval.

I also wanted to put all the unfinished armor into a different box but it turned out to be too narrow. I took this unpacked time to consider the inner strapping and inspect those provided by Mark at AP. His pattern using single snap sets with two instead of three at each joint between pieces. I'll likely use his pattern to avoid making additional strapping and consider adding more in future if needed. Overall I confirmed with some tape that the torso is perfectly sized for my current weight and could withstand a small weight gain in future.

Does everyone's bottom hang out from the back when you have the cod pulled up? Also it seems like the butt plate is longer than the kidney so some trimming might be needed.

Lastly I checked out the shins with some tape as this was an area I knew would be an issue with my calves being larger from youth spent playing hockey. Even giving a trench in the front I find them just too tight and a hot bath to reshape might not help much in this case. This

problemchallenge is for near the end of the build as I am working top down.

-

I did a small test of the dichloro methane and it made a junk piece of PLA both smooth and added a bit of shine. For welding pieces together I was able to join some flat junk pieces together so it shows some promise as a glue. Another test on more junk pieces and I should be ready to start joining the real thing.

Also the cheap brushes leave bristles in the PLA that if not removed become permanent. Went to the store and bought some better brushes.

-

1

1

-

-

11 hours ago, Digz Graavz said:

I also just completed an AP ANH stunt so feel free to PM me with any questions or check out my build thread.

I know, I've been watching you.....

-

1

1

-

-

25 minutes ago, DStep said:

Looking great Robert! Just a suggestion on the cover strips...you might want to trim the corners at a 45 angle. Those corners are sharp and can cause some annoying scratches.

Agreed. I've already cut them on my forearm strips but have not glued yet. I forgot to do so on the bicep, and also messed up the finish by sanding both sides of the strip, but will leave it for future clean up. The others shown in pictures are from Mark but I think his strips still look cool.

-

1

1

-

-

5 hours ago, ABS80 said:

Just sent you pics, can you please post them for me this will help others

Thanks

Mark (AP)

Just had a second look at the email from Mark and realized I didn't see all of the images on my phone. He included some completed shots which might be interesting to all AP kit buyers as to trimming edges and cover strips. I've already made some cuts to my armor so might not be able to follow these but they do look nice. I think the forearm and bicep looks nice and clean.

-

6 hours ago, lucnak said:

I built an AP kit last year and definitely had to heat gun the forearms a bit to get them to a shape where the owner could fit his hands through! Inside cover strips are a good idea here for strength. As mentioned, be careful with the heat gun; err on the side of caution!

My idea was with a bit of shape work I could reduce the trench between pieces but maybe not completely. I think I will connect one forearm as planned and after hot water consider reducing the trench.

-

1

1

-

-

26 minutes ago, ABS80 said:

Just sent you pics, can you please post them for me this will help others

-

Decided I needed to make some progress. So I trimmed the top of one of the biceps and made the cover strips. Might have went a bit light on the glue but will see tomorrow, can always take it off and try again.

-

3 hours ago, gmrhodes13 said:

if you have a look at some of the other AP build threads it will give you an idea what others have done.

Most of the other AP builds talk about the length but don't mention this width/curve of forearms. I should just glue with trenches as planned and hot bath them.

2 hours ago, p4ntb0y said:the AP kit looks awesome I had a kit untrimmed and messed up several pieces... live and learn.

Waiting for updates on your build thread.

-

1

1

-

-

Forearm parts came with different curves that do not match up.

So when you tape them together they don't natural come together on both ends. Taping one side you can see the other side is natural to have a wide gap.

You can push the sides together and you see the bottom connect with the top having a wider gap.

But with the magic of tape both sides can be pulled together and aligned.

It's been suggested that I connect one side then hot bath the pieces to make them join with less stress on the other side join. I'm thinking to also make the shape more oval or flatter to match the shape of my forearm. Also, I want to try to bend that edge up near the dimple instead of cutting it off for that "no return edge" look.

-

1

1

-

Husky68 ANH TK (trimmed AP)

in ANH Build Threads

Posted

Took a day off work and invited Bulldog44 over to my place for some armor building fun. It was great to ask direct questions and get answers to a bunch of questions. He brought some of his trimming scraps that will be great for filling the trenches in the forearms. Most helpful was the extra pair of hands and eyes to check body part alignments. We decided on the should strap snap placements and gap between chest and back pieces and glued in the snaps.

Once the rest of the internal snaps are done I can move on to harder parts like belt and legs. With a bit of time left we also put a layor of paint on my TD tube. I failed to notice that a previous contact with belt sander was not sanded back down. Another coat of paint or two might help but ok with a slightly marked up TD. Oh, I also used a ballon to hold the tube and keep paint from inside of tube while spraying.

Big thanks to Bulldog44 for making the trek and spending the day giving me a hand with armor.