Natalie

Member-

Posts

23 -

Joined

-

Last visited

About Natalie

Standard Info

-

Name

Natalie

-

501st Unit

n/a

-

They look pretty close to me (granted I've only been comparing images) The differences I see are simply softened details because their suits are vacuum formed. Vacuum forming isn't really suitable for making film quality costumes these days. I've seen people claiming all sorts of things about how the originals were produced. Having spent a few years in the film industry, designing and making armour, my opinion is the majority of parts were cast or sprayed PU, taken from moulds that would have been pulled off masters that were machined on cnc mills from 3D models. Some of the masters would have been 3D printed, like the snaps and forearm track details. The suits themselves would not have been 3D printed. I can't think of any printer that's capable of printing such large components and financially, that would be totally bananas. Milling has no such limitation. Vacuum forming these suits, to me, seems wasteful, expensive, overly laborious, harder for a non professional to work with and kind of pointless due to the loss of detail but, I'm not on their design team so, what would I know?

-

If you're adding talc, use the thinner version but, ultimately it doesn't matter too much

-

You can get ok results by mixing talc into cyanoacrylate glue to make a paste (this is basically what "bondo" is, except bondo has a polyester base) then hitting it with some spray kicker. It's not going to work on bigger seams but for smaller stuff it's fine. The problem with ABS is its chemical resistance.. Nothing really likes to stick with it chemically. You could try some epoxy with aerogel mixed in but, I think cracking is always going to be an issue on these suits though

-

I'm sure they did it the way they did for good reason My personal opinion is vacuum forming isn't really suitable for some things. Just an opinion though Perhaps by vacuum forming they felt they could produce parts that could be more modifiable to fit a range of body types whereas on films it's easy, you just choose extras that fit the suits

-

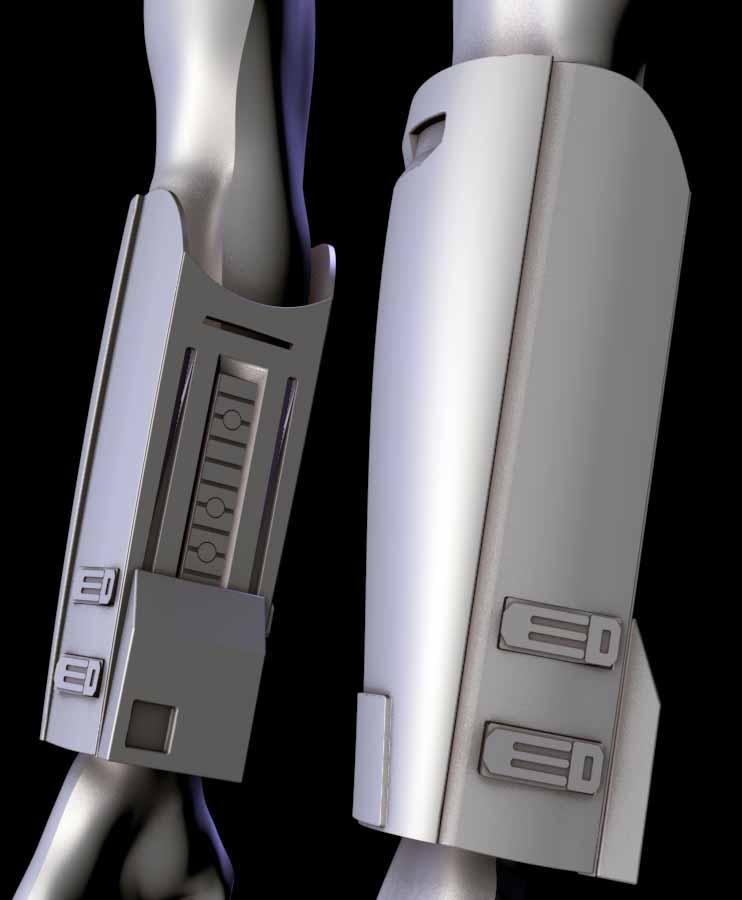

Thanks guys my aim is that the forearm part only have a seam where the flat inner section sits, so it would be two parts, with the sunken centre trak detail and clasp details added after. I'm trying to make this in a more similar fashion to the cast production armour than the vacuum formed ANOVOS suits. Ideally the bicep will be cast as one part also (with clasps added after) (Edit, the seam line on the model is just where the surface was trimmed, it wouldn't show up on a milled part... The models aren't anywhere near ready to mill yet, still loooooots of modelling to be done on even the most basic parts)

-

I'm glad they seem to be keeping them mostly white. I wasn't a huge fan of all the colourful ones in the prequels

-

slowly plodding away... playing with rough shapes and proportion.. ------------

-

Episode 7 Stormtrooper Helmet, WIP

Natalie replied to Dday's topic in Build Threads Requireing Maintenance

Hmmm. It sounds to me like people confusing language. Propshop is a fabrication facility at Pinewood studios. Off topic but, props get broken on films all the time. 3D printing has less to do with it than the fact that props aren't designed to be hard wearing by industrial designers, they're designed to look cool by concept artists. -

Episode 7 Stormtrooper Helmet, WIP

Natalie replied to Dday's topic in Build Threads Requireing Maintenance

I see. I was just curious as it would a be a strange thing to do unless you wanted to make at least hundreds of them.. The only "official" information I've been able to find says the helmets (and armour) were moulded polyurethane so, the could be meaning reaction injection moulding but even then.. that would be a weird thing to do, unless of course you wanted hundreds.. -

Episode 7 Stormtrooper Helmet, WIP

Natalie replied to Dday's topic in Build Threads Requireing Maintenance

Can anyone link me to an article or source about the costume parts being injection moulded? It would be really cool to see -

Episode 7 Stormtrooper Helmet, WIP

Natalie replied to Dday's topic in Build Threads Requireing Maintenance

Looks really great so far good luck with it -

Vambrace still needs looots of work.. The overall shape is too boxy, detail proportion and shapes are miles off, as is the curvature on the outer part.. I could probably get away with some of this stuff being off on a printed figure, being so small but, its miles out for a full size part... lots to do...

-

Do you mind me asking, the little faux snap-clasp details all over the suit, are they all the same size? (also, you really have done a wonderful job, the suit looks great!)

-

soooo much pretty plastic!

-