-

Posts

424 -

Joined

-

Last visited

-

Days Won

3

About Helotech

Member Title

-

Position

Centurion

Profile Information

-

Gender

Male

-

Location

Gander, NL, Canada

FISD Info

-

Centurion Granted Date

20200923

-

EIB Awards

1

-

EIB Cohorts

ANH-H

Standard Info

-

Name

Dave

-

501st ID

98695

-

501st Unit

Atlantic Garrison

-

Troops Completed

10

Recent Profile Visitors

-

Thanks for the continued links Glen! Jeffrey, let me know if you need any help with that helmet. Actually not that much work. Good luck! Dave

-

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Not really an update, but a funny moment bordering on an episode of a complete breakdown and crying! LOL First: I’m still waiting on the BlastFX kit to be shipped back. About 2 weeks ago we had some in laws visiting, so I was cleaning and vacuuming up my work bench area in the basement. As I’m vacuuming near a storage shelf I saw a hunk of what I thought was plastic from my 3D printer clippings. I bent over to pick it up, and lo and behold! The stupid missing magazine catch! And then I swear to all things holy that I searched every inch of the concrete floor between where I painted the E-11 parts and my workbench. I had even taken everything off that freaking shelf unit and slid it away from the wall to look behind it. Well, at least I have 2 now… Big shout out to Chris at BF for shipping out the replacement mag catch for free eve after I said I would pay for it. That company deserves a big hug! -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Well, it's been a long time since my last update. Sorry Glen... I contacted Blasterfactory about my lost magazine catch piece, and they graciously sent me one for free! Awesome company!!! I also contacted BlastFX and had some very good back and forth with the owner. Basically, the best solution for my fire selector problem was to send the entire system back to him for update of some components that would allow me to use the Blasterfactory rotary switch. That is going in the mail today and hopefully I'll have it back in a couple weeks. The bane of my existence! -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Thanks Tino. I considered that, but the BlastFX comes with 3 fire modes: Semi Auto, Full Auto and Stun. I would be losing one fire mode which I don't really want to do. I can possibly do surgery on this switch to add a ground, plus adjusting the contacts somehow. It would not be difficult per-say, but could end up not working. I have sent BlastFX a PM through FB to see if there are solutions, plus I have the CO of Great Lakes Garrison possibly sourcing a switch. I just really want to get this blaster done as I am going to a troop at a Star Wars themed wedding and would like some flashy light up blasters for people to see. I'll be bringing my DLT-19 which has BlastFX, but this would be icing on the cake. -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

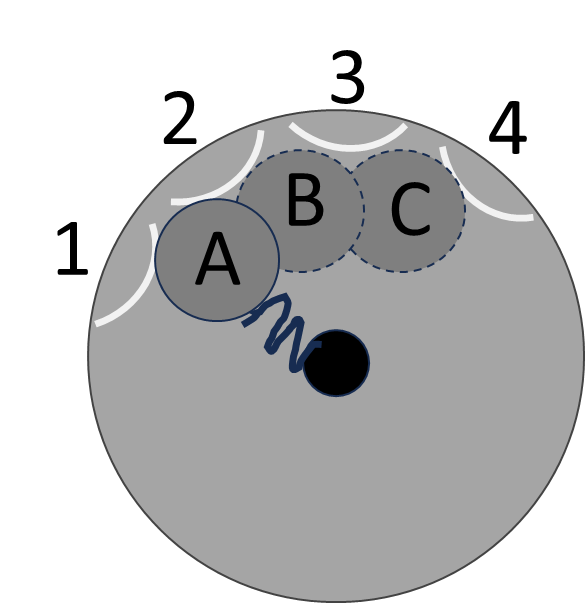

Back from the camping which was awesome! Tino, the issue is the switch included with my Blaster Factory E-11 will not work with the MY BlastFX system (stay tuned for why Adam...) So, the switch diagram provided by Adam for the Blaster Factory switch is incorrect. 1- 4 are the curved contact points inside the switch. They are attached to corresponding soldering tabs on the outside of switch as seen in Tino's post. A is the little metal circle that is inside the switch lid. B and C are alternate positions as you rotate the selector. The squiggly line between A and the central black circle is a spring inside the switch lid. See my previous pics. There is no "common" ground in this switch as is required by the BlastFX program and wiring The little metal circle sits between 1 and 2, not ON TOP of 1 as seen in Adams pic. Therefor, A will short out contacts 1 and 2. As you rotate the selector to choose another fire mode (position B ) the metal circle squishes against the spring and snaps into position B and now shorts out 2 and 3. Same for position C. So, Adam, you are correct in your explanation of what to do with the BlastFX memory card. HOWEVER, I bought my system in 2020 or early 2021 (I believe) before this was probably an issue and solved. I'm just getting around to installing it now. I just confirmed on my card that there is no Fieldmarshall setting for my version of BlastFX. I've attached a link to the BlastFX FB page video concerning the build he did. At timestamp 14:30, he explains the switch issue as well. In this video he hasn't solved the issue yet. BlastFX in Blasterfactory E-11 Hence, I am on the search for a switch that will work (with a common ground). I know the BlastFX owner does an amazing job, and helped me solve an issue I had with DLT-19 build. I shipped him my BlastFX harness for the DLT-19, he fixed the issue then updated the software for free. I just paid for shipping. If I can't find a good switch I may have to do the same with this one... -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

So I ran into another snag, this time with the fire selector switch provided by Blaster Factory (C&K switch). It can't be used with the Blast FX system. The next follow on issue is that the Blast FX fire selector does not fit into the Blaster Factory grip area. The switch housing (not the shaft that the selector lever attaches to) is too big. The thin side grip panel can't be screwed down. I have gone on the C&K website to try and find an appropriate switch, but it is very difficult to narrow down using their system. I posted this problem on the BlastFX FB page, and the CO for the Great Lakes Garrison, Ed, got back to me as is doing some blaster work as well. He is willing to go to an electric store and pick out an appropriate switch. I live in a small town without great selection of specialty items, so this is a god send. Thanks Ed!!!! In a video on the FB page the developer stated he contacted Chris from Blasterfactory to possibly change the type of switch he uses. Left pic is the Blasterfactory rotary switch installed.. This is a view of the bottom of the grip frame. It fits, but can't be used with the wiring in the electrical system. See later pics. Compare this to the next photo showing the BlastFX switch in the same place. It is about 3 mmm to large. Two switches side by side. I actually pried both open to have a look... Her is the inside of the C&K switch. The lid and post are on the right. The metallic disk sits in a small groove on top of a spring. When you rotate the selector, the little disc jumps into the recessed spaces in the body on the left. You can see 4 metal curves that extend to leads on the outside where you would attach wires. As the metal disc jump between the curves, it shorts out 2 contacts at the same time. This also give you those positive "clicks" as you select different fire modes on your blaster. The Blast FX switch is completely different. This is the inside of the base. Sandwiched between this bottom piece and the similar top blue piece is a little green disk with metal contact circles (green disk not pictured. You can see 5 contacts inside; 4 smaller "mode" contact points and a larger "common" ground. This common ground is the whole difference between the two rotating switches. Without a common ground the BlastFX won't work. Out of the 4 mode contacts, only 3 are used. You can see the leads coming out of the top of the unit. The far left one is not connected. So, my task is to acquire (hopefully with the help of Ed) a rotary switch with the dimensions of the Blaster Factory C&K switch, but the workings of the BlastFX one. I'm heading camping for the long weekend, so I'll clear my head in some fresh air, drink rum by the fire, and destress about what I thought was an easy project. Sorry Glen. Hate to disappoint you -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Thanks guys! Build has been put on hold for a couple days. I somehow lost the oval shaped magazine catch that fits into bottom of magazine housing. I've torn apart my workshop a couple times but still can't find it. I've contacted Blasterfactory to see if I can buy another one. Still waiting to hear back on that, but in the meantime I'm heading back into the basement to see if I can do a last ditch find of it. I'll start feeding wiring components into the blaster until then. Tino, I'll try to be going the realistic route. It's just a question of how to achieve it best using painting as you described. -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Small update. All the main pieces are painted except for the bolt. I actually thought the bolt was supposed to be bright aluminum, but ref pics of real Sterlings show them as a worn blackish metallic color. I basically sprayed all the body pieces a rattle can semi-gloss, but now I think it's too shiny. It leans more towards the gloss instead of the semi. I'll see how it all looks when put back together, then maybe overspray with a dull coat. I'm also trying to figure out the speaker placement. Black is the new black. Some pieces aren't pictured as when I brought them into the better light of my workbench I noticed I had missed a few areas with the spray paint. Pictures of the speaker sitting in the back end of main tube. The little soldering stubs (it is sticking out of the right hand side of speaker in the pic) just catches the edge of the main tube. The whole assembly is about 1mm to wide. My thought is to cut two grooves opposite each other in the main tube to allow the soldering connectors to just slip inside. Once the new wire is attached (remember they snapped...) I'll wrap the speaker outer ring in electrical tape to protect everything from shorting against the tube body. And my scope greeblies arrived! I ordered a pack of 10 off Amazon. If I don't hear from Joseph about his greebly bits, I'll take a look at what he designed and make my own. It's not a dig at him, I just know he's got stuff going on. I'll just have to decide if I will install just one at the front of the scope, or two, with one over the rear lens. Cheers! -

Hey Robert, Thanks for another referral Glen! I purchased the SDS almost 4 years ago and brought it to Centurion standard fairly fast. It does take some work, but really wasn't that hard and I like the quality. When I compared my armor to some other TK's at troops mine seemed a bit "better". Not sure why, but of course I'm biased. I even had those TK's comment on how nice mine is. I do like the color better on my armor as it is a very light cream color, like the original TK's rather than a stark pure white. SDS is pricey, but after looking at other peoples builds it did seem like mine was actually less work, especially if you are only going for basic approval. It is all pre-trimmed and assembled of course, so if you are not a "typical stormtrooper size" of somewhere around 5' 8" to 6'. and around the 180lb +/- range, it may not be for you. There is definitely some wiggle room where you can take apart the armor pieces and reglue to your own size. But this is true of any manufacturer. Some manufacturers sell there armor in various sizes to accommodate taller / shorter / skinnier / beefier body types. Other makers have you cut their armor pieces out of vacu-formed sheets and that can be allot of work. Some people get caught up in the whole SDS court drama , but that never bothered me. I didn't know about it until after I had the armor shipped to me. It's your choice to research it and decide. If you have any questions the network here is great! The forums can be daunting as there is SOOOOOO much info, so start saving links (like those above) in a build folder on you computer. If you need anything specific, don't hesitate to message myself or anyone else. Good luck, and have fun!!!!! Dave

-

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Another small update. I ground out the brass scope ring that holds the scope display. I also started the painting with one coat of primer grey, and then there will be 2 or 3 coats of semigloss black. I'm sure some might rub off when I carry out the electronics install, but I could easily touch it up or leave it as normal weathering. I'm debating whether to highlight the "original" stamped markings on the scope and the mag well in white. I don't believe the ANH blasters had the white lettering. Have to check the references... -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Small update. Fixed the back cap issue by grinding away the little nubs on the inside of the cap. This allowed the cap to sit at 12:00. The back cap locking lever was repositioned Drilled out the fire selector switch hole for the larger BlastFX switch. Hopefully this will fit in the grip as it is a bit thicker than the Blasterfactory one. Drilled a hole through the scope mount and scope rail in preparation for wire running. Spent lots of time trying to figure out component location and wire routing. Nubs inside the cap were grounded down by about half, allowing the cap to rotate to the new position. I thought of drilling new holes and repositioning the cap locking ring, but the new holes would overlap the existing ones. Old locking tab position vs new one. Hole drille dout and BlastFX fire selector switch in position. This post is taller than the old one, so it may need to be cut down. Also, the lever that attaches to this is 1/2 moon shaped, so I will have to cut this in half vertically as well. Difference in thickness. I haven't tested the grip to insure the new switch will fit... Scope mounting holes before drilling wire access holes. Thankfully the scope is nice soft aluminum. The mount is sheet metal but easily drilled through. Scope wiring will run up through the cope rail mounting hole at the front, along the underside of the rail, and up into the scope. The scope display circuit board in the front brass ring. I will take a hint from the Blast FX FB page about this build and grind out little triangular slots in the brass. This will allow the dirsplay to sit into the brass about 1 mm or so for security. And here is one issue I had with my DLT build. These wire are VERY small and any minor manipulation leads them snapping off from the components ate the solder joint. I had simply positioned everything in the blaster as a test, and as I was manouvering the speaker out noticed a wire had snapped. Just adds to the fun... What I've come up with for the BlastFx component location. I forgot to add the scope and Hengstler counter for the pic, so I just blocked them in. I wanted to keep the magazine with all its guts intact, but I don't think this will be possible. I will place the Main and charging circuit boards in the magazine well, then slip the now empty magazine over top of the two. The laser will be mounted behind / under the bayonet lug. You should see only about 1/2" of wiring from the laser before it disappears through the main body cooling holes. The light strip will be glued along the inside bottom of the main tube. Battery will be attached to the inside top of the tube. It shouldn't be visible as I'll wrap it in black tape and the T-tracks will cover the top and side holes. The little sliding on/off switch will be tucked away in one of the cooling holes on the bottom, or I may move it to the Hengstler counter. Not sure yet. There is a push button mode switch that is used to set preferences, cycle through digital menu's, etc. I'll try and rig this to the existing Hengstler rest button on the counter. The speaker is the main issue. I want to attach is to the back cap so it points forward, but this is not possible. The speaker could JUST fit inside the tube if it wasn't for the little soldering tabs that stick out the side. If I lay the speaker flat and rotate it slightly, it can just fit. I will have to trim back the main cocking spring slightly so it doesn't jam up against the speaker. I may also install a carboard tube (painted black) in the main body so it "warms up" the sound. When you put a speaker in a metal tube it makes it sound very tinny. Stay tuned! -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

Quick update after some minor blaster surgery. I mostly reassembled the E-11 so I could get a better understanding of where I can place the electronics. The muzzle cap had a large groove cut into it with a hacksaw and various Dremel bits to allow the installation of the muzzle flash device. I won't be using the kit barrel as it is really not needed. it can't be seen and leaves less room for electronics in the forward tube. I'm trying to place all the electronics in the main tube so I can keep the guts of the magazine in place I removed the installed fire selector switch in preparation for the BlastFX one. I found that the cocking action is very stiff and "grindy". You can actually feel and see little slivers of aluminum powder and shavings every time you weenie the action. This could be worked out over time, but I've never seen anyone cocking the action on an E-11 in the movies, so I don't need it here! Blaster is mostly reassembled. You can see that the selector switch is removed. I'll have to drill out the hole slightly to accept the post from the BlastFx version. I may also have to cut the post down slightly so the selector lever sits flush with the left side of grip body. And yes, I was listening the Gordon Lightfoot while grinding away. Something soothing about The Wreck of The Edmund Fitzgerald as you grind away at metal... I discovered a small issue with the end cap that I hadn't noticed before. The main tube has a grooved locking ring attached with 3 screws (visible in image) to the rear of the tube. This allows the end cap to lock into place. You basically line up little tabs on the inside of the cap with the grooves, push in slightly against the main spring, and turn clockwise. Once locked into place my end cap sits clockwise slightly, with the top being aligned at roughly 12:30 instead of 12:00. Locking ring on the Blasterfactory website. How my end cap sits vs how it should attach: On the real Sterlings there is a locking device (tab?) on the bottom just forward of the end cap. It has a spring and pivots when pressed which disengages a little tab that allows you to remove the end cap. Blasterfactory has included this little locking device with a spring, which is nice, but it is mounted about 1/4" forward of where it should be. It is also slightly off the bottom centerline of the main tube. Locking tab too far forward. The backend should overlap the end cap. There is a little stub on the inside of the locking tab that should sit in the small groove in the end cap. In the right image you can see the centerline of main tube in blue. My cap is locked in position with the center in green, and the black locking tab is off center in red. These "should" be easy fixes. Both the end cap locking ring and the black locking tab are held on with screws. I just have to re index everything and drill new holes. The muzzle cap surgery took a couple hours of cutting, grinding and filing down. I started with a couple simple hacksaw cuts with the muzzle held in a vice. I then used various Dremel bits to hack and grind away at the material. Thankfully this is aluminum and not steel! Unfortunately, the Dremel skipped a couple times and put some minor dings into the nice smooth paint job. These will be easy to sand out, but will necessitate a new paint job. Here it is basically done. I had to grind a small rounded bit out of the forward end of the slot to accommodate the led bulb of the flash unit. It's hard to capture in a picture, but I also had to grind a rounded groove at the bottom of the channel to accept the round circuit board of the flash unit. If I attempted to have the entire groove the depth needed for the flash unit, I may remove too much material and get close to the front sight cutout. Flash unit in the groove. The flash unit circuit board is a rounded "star" or "flower" shape, and one of the points / petals sits in the additional round groove at the bottom of the channel. In this pic, the muzzle piece is held upside down. So the muzzle sits just at the bottom (top in this pic) of the big hole. If I tried to center it I may remove too much material and get too close to the front sight groove. By me carrying out the surgery the muzzle flash board sits about 1/2 to 3/4" more forward. so it will be seen better. Back to the workbench! -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

A quick general overview of what I will be dealing with. I've also updated the links in first post with my DLT build so you can see functions of the BlastFX system. I received the blaster fully assembled, which may have looked interesting going through customs. I disassembled everything last year in preparation for this build. Here are all of the parts, with the BlastFX system at bottom right. Some components, like the folding stock, grip assembly, etc, will be broken down further for ease of painting and wiring installation. I'm still deciding where all the wiring will go. There is only so much length of wire, so I have to be careful about where I put everything. I can use wire extensions like I did on my DLT build, but this adds unnecessary bulkiness to some wires which could hinder the build further. I've seen a couple builds where much of the electronic circuit boards were in the mag and mag well. This allowed the rear main tube body to remain relatively empty. You could then pull back the cocking handle and bolt as I guess something to do...? As I can't see this having a purpose in the "real world" of Star Wars, I may transfer some electronics to the main tube. As long as they remain hidden when viewed through the large cocking handle groove I'd be okay with that. I'll have detailed pics and diagrams later, but here are the blast FX components and possible installed locations (clockwise from bottom of wire harness): Main control circuit board. It's hard to see, but there are two little R/B wire coming out of the unit to the left. These may have been from the vibration unit I had to steal from this kit for my DLT. Can't remember now.... In mag well or main tube below SMG bolt. Speaker main tube at back Barrel lighting strip attached to inside bottom of main body tube so it reflects upward Muzzle Flash Device Black muzzle cap Laser Possibly shining out of a small hole drilled in front of magwell Mode selector button Attached inside the Hengstler counter and activated by the original counter "reset" button Trigger switch Inside grip behind trigger. Blaster Factory includes one and this is a match, but it is already wired into the BlastFX system Rotary fire selector (single shot, auto and stun) BlasterFactory includes a rotary selectro, but from my sources it is finicky and hard to wire correctly with the BlastFX system. I'll probably just remove it. Scope display (little black square that needs to be soldered to wires) Blast FX left this disconnected for easier routing of wires into the scope. VERY smart and thankyou! Back of scope Main display (little black rectangle). Same wiring considerations as the scope Inside Hengstler counter display area Grip vibration unit (little black circle). My DLT hand one and I remember the thin wires broke at the unit. I think I had to steal the one from this kit to service the DLT. I then ordered a few more on Amazon. I'll have to attach this vibration unit to the wires to see if that is what they are for...Somehwere in grip Main battery: 3.7V 2000mAH 7.4Wh I may have an issue with this rectangular battery. It doesn't fit the mag well in a nice way, and may not leave room around it for the other pieces. Magwell or main body. TBD Charging circuit board for battery. This is an after market piece I bought online: Powerboost1000 Charger. It includes a USB charging port which I will have to incorporate into the blaster somewhere. I'm using this so I don't always have to remove the battery for charging. I'm not sure if I want to cut a USB size hole into the body of the blaster, and I don't want to disassemble the blaster to get at this USB port, so I may put the circuit board somewhere easily accessible like behind the main tube rear cap, or in the mag well behind the magazine. Magwell or main body On / Off sliding switch for power source. Small black thingy to left of the charging circuit board. This has to be somewhere easily accesable. Possibly hidden at back of magwell, or in Hengstler counter Detailed pic of the displays, included scope display magnifier and red filter, as well as a vibration unit. Battery, charging circuit board and sliding on/off switch: I actually felt real bad about taking apart a real Hengstler counter to add electronics. I debated purchasing another blaster, keeping the counter intact to replicate a screen used one, then having another with electronics for trooping. Unfortunately I can't justify that cost. The little baggie on the left is all the tiny counter parts I won't be using. There's a surprising amount of tiny springs, gears, pins and bushing in this little device. There will be more detailed shots of this and other pieces as the build continues. The magazine. I paid extra to receive a real sterling magazine that was cut down just like the movie used ones. I forgot to include the magazine "roller follower" in this shot, and there are some screws and springs missing from this shot. You'll see them later. I probably can't use any of the internal mag bits because a few of the electronics will sit in the mag and mag well because of lack of internal space in the blaster. Main body, t-tracks, muzzle cap, fake barrel and front sight. The way that Blasterfactory designed this all to go together, while retaining the external features of the Sterling perfectly, is quite ingenious. You won't be able to see the barrel as the T-tracks block most of the holes. And now the first build issue.... This is the muzzle cap that screws into the front of the barrel unit, and pictured is the muzzle flash device. Technically, the flash device will have to fit somewhere inside the muzzle cap shining out the front, but there is no way to do this right now. I was thinking I cold lose the barrel, but it is used to attach the front sight, as well as the back of barrel might be used to stop the bolt from sliding forward or rattling around. I could cut a groove into the bottom of the muzzle device to allow the muzzle flash unit to slip into, but there is an issue with this (next pic) This is the backside of the muzzle device after it is detached from the barrel. You can just see that the muzzle flash device circuit board partially covers both screws holes. This prevents the screws from passing through and screwing into the barrel unit. I can't trim the circuit board down sufficiently What I could do, and would require the same surgery is: Cut a suitable groove / slot to slip the muzzle flash unit upwards into the muzzle device. Cut the screws down by about 1/2" When it come time for assembly, I just glue (E6000) and clamp the barrel to the back of the muzzle device Glue the remaining heads of both screws into their holes. This will allow the appearance that they are gripping into the barrel. The included round rotary and trigger switches. They will be replaced by the BlastFX versions. You can juts make out a hole above the black trigger switch that will allow wires to pass through. I'll have to makes sure that the BlastFX rotary switch functions line up with the Fire /Auto / Safe marks that are on the other side of the grip. That's it for now. -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

So far I just laid out all the parts and the BlastFX to see where I will put things. Unfortunately, I have already have run into, "oh well darn" situation. I'll explain more when I post the pics. -

ANH Blaster Factory E11 with BlastFX System build

Helotech replied to Helotech's topic in ANH BlasTech E11

I'll rush this just for you...