-

Posts

479 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Everything posted by Thrawn's guard

-

Richard I am glad to have been able to prevent you making the same mistake. I think that this is really what the forum is all about. Sharing both what works well and what doesn't so that people that follow can pick up tips and suggestions. In the end we all help each other and as a result the standards of our completed blasters can only get better over time.

-

You've carried out Some more great work on your blaster. I particularly like your method for adding the serial number and appreciate the research that you and Tino have done regarding the serial number combination. If I can achieve a similar standard of build to what you are putting together I will be very happy.

-

Thanks for the feedback it is much appreciated. With regard to the snapped piece I posted this was hopefully to help others avoid the same issue but as Michael says above these things sometimes happen. The important thing is that these things are fixable and this community is a fantastic resource to find solutions to all sorts of issues. Brian/Richard I hope your builds go well. I'm sure that we will all get there in the end.

-

Well on to the last thing for tonight......a quick clean up of the trigger and guard. After the issue with the cutters earlier I decided to simply rub the piece on a sheet of sandpaper. In very little time at all the trigger and guard could then be removed from the spare resin and tidied up with gentle use of a fine file. The rest of the clean up will be done over the weekend.

-

I just had a thought with regard to the front sight pin and was wondering what the opinion of the E11 experts, (basically anyone who had built there own blaster or has access to a real sterling), is. Do you think that using a screwdriver tip i.e. the sort that are interchangeable and can be purchased from a pound shop or dollar store make a good sight? This would be an alternative to the details I have seen on here where a screw/bolt is ground/filed to the correct shape. The top could be shaped to the correct angle. Below is a picture of a selection of the typical sort of things that I have in mind.

-

Michael I love the work that you are doing here in particular the working butt cap retaining clip and magazine release button. These are the types of details which really do make a difference. I had a similar idea with regard to adding serial numbers to the ejector port but have been struggling to find small enough metal stamps so it is good to see that they are available. Did you get the channel for the butt cap retaining clip from the completion kit ? The only problem with great work like this is that it keeps giving me new ideas which means my list of items to carry out is forever growing!!!!! Anyway great work and I am looking forward to continuing to read your build thread.

-

I also intend to order the monocular and a counter to allow me to upgrade the scope and counter. My intentions are to carry out a number of modifications/upgrades for example hollowing out the scope and fitting lenses, adding the spring within the barrel, upgrading the counter to have a working button, have a working selector switch and trigger. I may also look at incorporating one or two other upgrades if any come to mind during the build. To be honest I can't wait to get my teeth in to this project. Throughout the build any suggestions, observations or queries will be most welcome. Also if anyone has any queries regarding how I have done something please feel for to ask (I will try to include sufficient pictures to convey what I am doing).

-

Well my Doopydoos resin kit arrived a few days ago and I have been spending the time since reading through many of the great build threads available here. The first job was checking that my kit includes all of the parts (Which thankfully it did). Having checked the parts were present I have carefully cleaned the kit in warm soapy water to remove all traces of the release agent and aim to tidy up and sand the parts as required tomorrow after work. Whilst cleaning the parts I noticed a couple of minor errors in the cast, (presumably air bubbles), which I will make good. What product is recommended for this type of small repairs i.e. Green stuff, car body filler etc ? EDIT - After further research I have decided to carry out the minor repairs using green stuff modelling putty. EDIT - Please find a link to allow you to download the M38 scope cross-hair sets as indicated on post 136 of my build thread and shown installed in posts 210 and 231. They can be printed as they are for installing on the monocular lens housing or rescaled as required for other applications. Please feel free to download and use https://app.box.com/s/o1ln2s40qmklzuslwrxhljji3upkc8pb</a>

-

They have some more on stock at the moment.

-

Hey Tim I have just received my Doopydoos E11 kit and thought it a good idea to read some of the build threads and came across this one. I just need to say that what you have built is amazing but what's even more extraordinary is the fantastic effort in putting together such a detailed and helpful step by step guide. I will definitely use this thread as my main point of reference in my own build and am sure that what you have done here, along with the helpful comments and suggestions from various other contributors, has and will help many others. It's great to see so many likeminded people working together for the good of everyone. For the glory of the empire.

-

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making

-

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making

-

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making

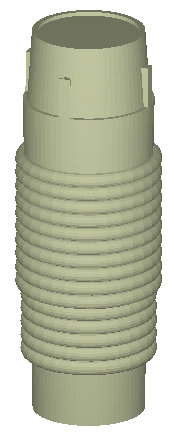

Hi Joseph I'm glad that you like it and thanks for the feedback which is always very welcome. I also like to build things so thought that this would be a reasonably straightforward first venture in to the world of prop building. I have actually modelled 3 variants of the C1 comlink one of which includes the larger diameter 'rings' rather than the fins shown in my earlier photographs so I will probably end up building that version too. Just curious but do you know why the accessories are approved for hero but not stunt builds ? Also if you could PM me the photos that you mention above it would be much appreciated as I do intend to look at producing a number of star wars related props. I have actually modelled a number of different items already as a means of getting to grips with the 3D modelling software. -

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making

I hope to have this finished today so will post a picture of the complete build once done. Do any troopers out there wear these with there armour ? Once completed I may look to produce a light sabre hilt and then it will probably be on to the big one..,....my Doopydoos E11 conversion. At least doing these side projects will give me some time to save up for my armour kit. -

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making

Ok the picture above is how it stands at the moment (My first attempt at a prop). I still have some more work to do on this including black gloss paintwork to the central section, a metallic texturing to the tip and a metal mesh insert. I also have some filing and cleaning up but hopefully you get a idea of what I am putting together. -

SoroSuub C1 Comlink

Thrawn's guard replied to Thrawn's guard's topic in The Foundry - Armor and Prop Making