-

Posts

41 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Posts posted by oneal

-

-

i'm afraid to use a high speed power tool to cut the thin plastic.

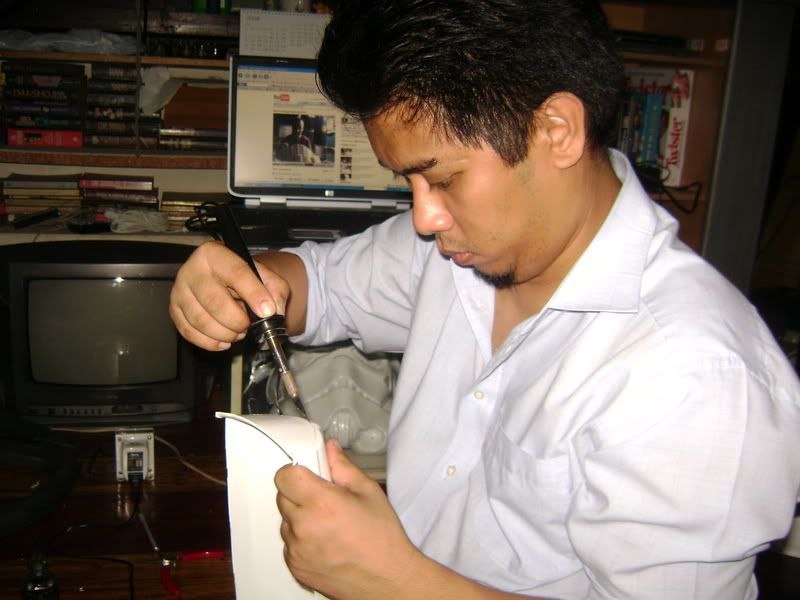

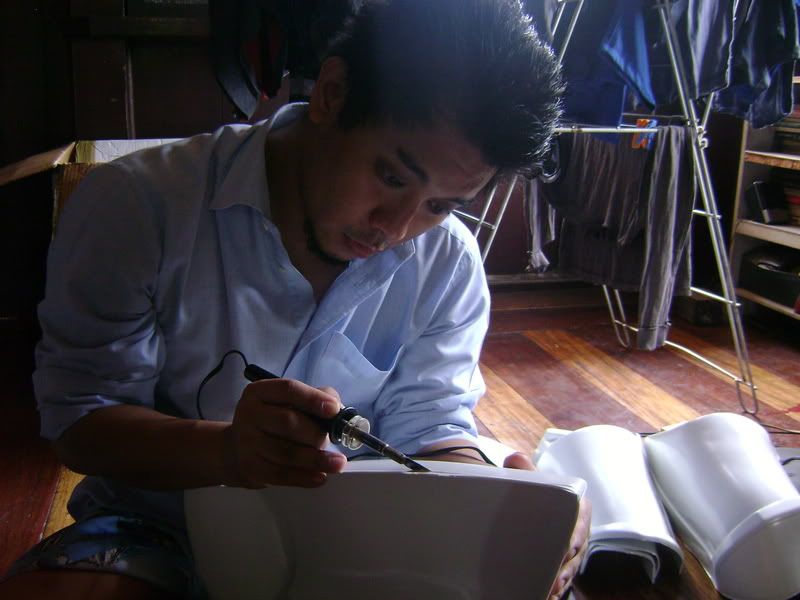

i've been using a Hot Blade X-Acto knife i bought at Fry's Electronics for about $15. it plugs into a 110v power source and heats the blade enough so that it melts the plastic slightly while you score it before snapping the pieces off

i think this is a better and safer method since you don't need to use too much pressure or force to cut through the plastic, just a few light passes are enough to make a sufficient scoring for a clean break

-

if you notice, i left a bit of a "lip" at the ends of the armor pieces just like the legs and body. this makes the armor look a little more solid and robust compared to just thin plastic. i might have to trim it down a little more when the pieces are clam-shelled together if my hands don't fit through the hole.

i'll take more closeup photos tomorrow

-

test fitting the arm pieces:

-

after i score the piece with the knife, i sometimes make a couple of passes with the standard "cold" x-acto knife while slowly bending the piece, it also helps to make perpendicular cuts with shears or tin snips so that the part you are removing comes off with less resistance

its also very important that you do not rush working on the armor since this usually leads to mistakes or worse, damaged armor

-

the problem with using the hot blade x-acto is that your grip is a little farther from the blade than usual compared to a normal x-acto, it makes it harder to do more precise cuts, there is also the risk of accidentally grabbing the hot portion of the knife.

sometimes the plastic is thin in certain areas so the hot blade just goes right through it in one pass so please be careful where you put your hands. i was tired and sleepy while working on the armor and burned my fingertips at least twice on both hands.

-

the bicep pieces were molded together and the clearance between the parts was rather tight making it hard to fit my rather large tin snips in the gap, instead i decided to cut them with the hot blade. this took much longer than the legs.

-

thanks for the words of support from the FISD veterans

anyway, back to work:

i finished cutting the legs in one evening and set them aside

then i worked on cutting the arms, while the legs had long straight, flat areas, the arms were smaller and the curve for the openings were significantly tighter compared to the legs. i had to make little cuts to follow the angle of the armor, this made it harder to make clean scoring and then snap.

-

i bought the Hot Blade at Fry's Electronics in LA last December 2006, while my girlfriend was training with the other 501st for the Rose Parade, got it for about $15 with a lot of accessories and attachments, unfortunately for me, it runs on 110volts while standard power line voltage in the Philippines is 220v, hence the need for a step-down transformer. it is very useful for other projects like wood etching, soldering and carving into fiberglass costumes before using a dremel.

-

starting to trim the armor:

i marked the guide lines with a soft pencil then i used a hot blade x-acto to lightly score the plastic. this is to ensure that the blade does not accidentally slip when i use too much pressure with a standard cold knife. i repeatedly cut the gap till it widens enough when i slowly bend the pieces apart.

much faster than cutting each part with a dremel disk when working on fiberglass

-

other tools:

my girlfriend's cat Snowball helping out

-

tools of the trade:

tin snips

hot blade x-acto knife

-

here are photos of the armor out of the box

-

while i've assembled or helped to assemble numerous costumes, including a Bikerscout, a TIE & X-wing Pilots, Jedi, Threepio and Vader, only one actually fit me - my former TK armor was a fiberglass suit similar to the FX armor, after 3+ years in the 501st, i finally decided to upgrade to the more accurate AP suit. i ordered it in late March and it finally arrived last friday, May 2.

i started work on trimming on Monday May 5 after coming from work and its a lot easier than cutting fiberglass with a dremel, and a whole lot neater.

i'll be posting my progress here, and hope to get advice from the experts

-

TK-1330 from the Philippine Outpost requesting status activation

thank you

TK-1330's AP assembly progress

in Build Threads Requireing Maintenance

Posted

after a brief hiatus, i finally got back to working on my AP armor, i started cutting the torso pieces in the same way as i did with the limbs.

using the now seemingly popular hot blade x-acto knife(available on ebay or amazon) i made quick work of the back/kidney armor.