All Activity

- Today

-

teflontusk joined the community

-

rendazer joined the community

-

[76] TK-39093 Troop Log (Hong Kong Garrison)

giskard8 replied to giskard8's topic in Field Training Exercises

76) 20/04/2024 - Books for Love 2024 @ Taikoo Place (QuarryBay, Hong Kong Island) -

Bones1987 joined the community

-

To be honest, I'm not ruling anything out at the moment. Everything anyone is mentioning is all me learning, and stuff I add to my search terms. The mag well doesn't have a serial number on top or bottom. I took a pic of both, but given forum image size limitations, what I uploaded was just the underside and the scope. But no visible serial numbers anywhere. The former owner is away at the moment, but his son will ask him to get back to me when he returns, so we shall see.

-

jasper 1023 joined the community

- Yesterday

-

Solid resin E-11, reportedly from the UK about 10 years ago

revlimiter replied to Peter Hamilton's topic in ANH BlasTech E11

At a glance, it's certainly not a vintage Hyperfirm. I don't believe the Hellhounds ever looked like that either. Just as data points. You probably already know that, I just wanted to add my own confirmation. The serial on the gun would be on the top side of the mag receiver. Or possibly above the clearing strip on the bolt. If anything is cast in at all, it would be in those spots. ... heh, you said resin, not rubber. Doh. Ignore the first paragraph. -

ScottL joined the community

-

TK-13239 Requesting ANH Stunt EIB Status (AM) (1071)

Sawanator replied to Sawanator's topic in Request Expert Infantry Status

Many thanks. I have stickers, so will give that a shot. -

[5]TK-23072 Troop Log (Social Media Consent)

budu1 replied to budu1's topic in Field Training Exercises

Mision 5 03/04/2024 (MAD) SEMANA DE LA SALUD DE GETAFE -

[5]TK-23072 Troop Log (Social Media Consent)

budu1 replied to budu1's topic in Field Training Exercises

Mision 4 [BURGOS][06/04/2024] 40 ANIVERSARIO ASOCIACIÓN AUTISMO BURGOS -

[5]TK-23072 Troop Log (Social Media Consent)

budu1 replied to budu1's topic in Field Training Exercises

Mision 3 04/04/2024 - GUADARRAMA (MADRID) - VISITA ADISGUA como colgar fotos en la nube -

[5]TK-23072 Troop Log (Social Media Consent)

budu1 replied to budu1's topic in Field Training Exercises

Mision 2 16/12/2023-MÓSTOLES (MAD) - MERCADILLO SOLIDARIO COLEGIO VILLA DE MÓSTOLES -

Mision 1 22/11/2023 – MADRID – VISITA HOSPITAL UNIVERSITARIO LA PAZ

-

TK ANH Stunt by CloseTheBlastDoor

CloseTheBlastDoor replied to CloseTheBlastDoor's topic in ANH Build Threads

Thanks for those reference photos! Due to an interview, hand pain, and getting ready for a vacation, I've not spent much more time on this, but I hope to have a few more hours soon to plug away at this. -

TK ANH Stunt by CloseTheBlastDoor

CloseTheBlastDoor replied to CloseTheBlastDoor's topic in ANH Build Threads

Thank you for the advice, ShaSha! I agree that getting the strapping done is the next logical step. I did already trim the large tabs from the backs of the straps, so we'll see! -

TK-13239 Requesting ANH Stunt EIB Status (AM) (1071)

Sawanator replied to Sawanator's topic in Request Expert Infantry Status

For the Tube strips, are there any tricks to getting that lined up properly? It's one of the last things I have to do Also, to take the old ones off, is it just elbow grease? -

If you haven't figured it out, Glen Is the G.O.A.T when it comes to anything Storm Trooper

- Last week

-

Thank you so much! I appreciate your help!

-

Albums

-

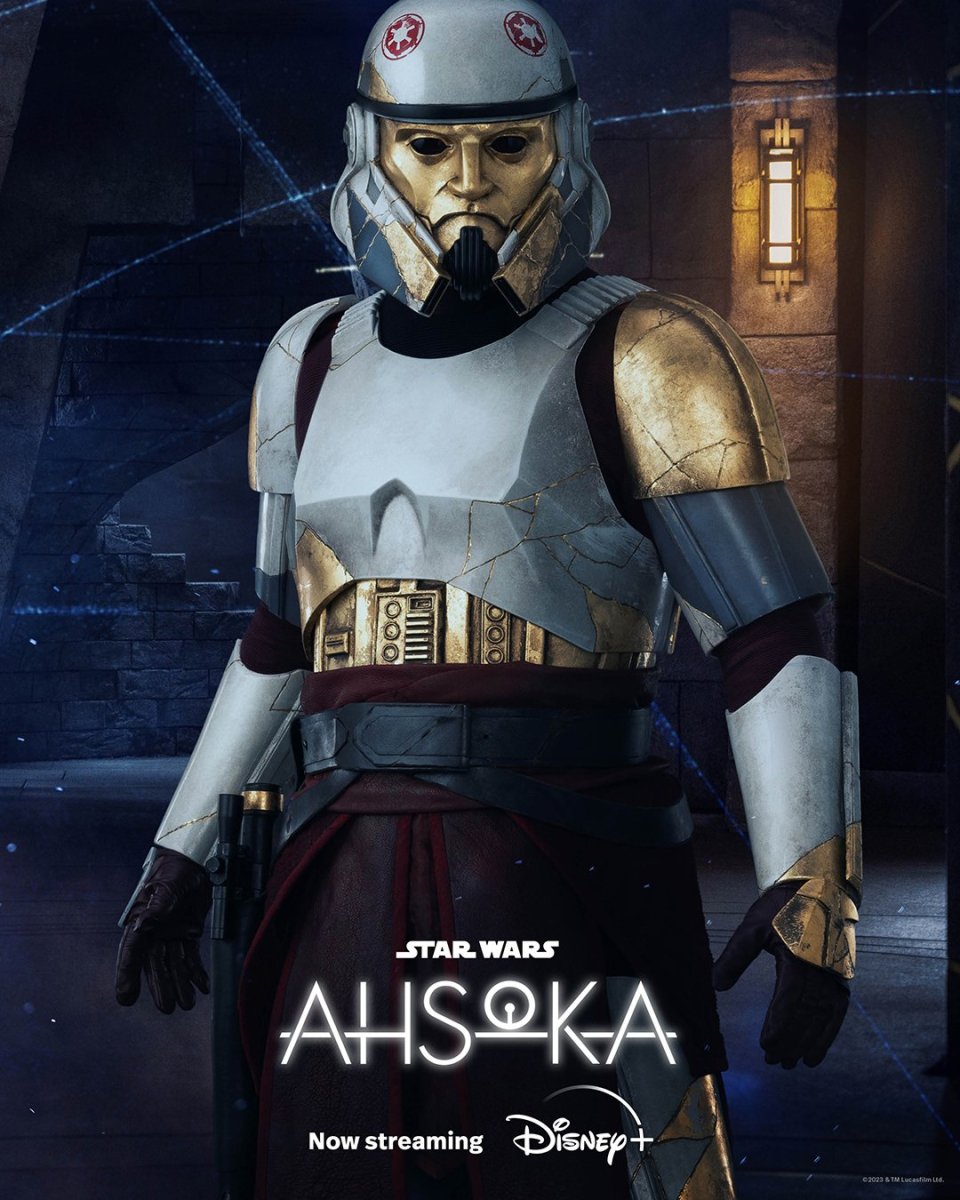

Captain Enoch (Ahsoka)

- By themaninthesuitcase,

- 0

- 0

- 2

-

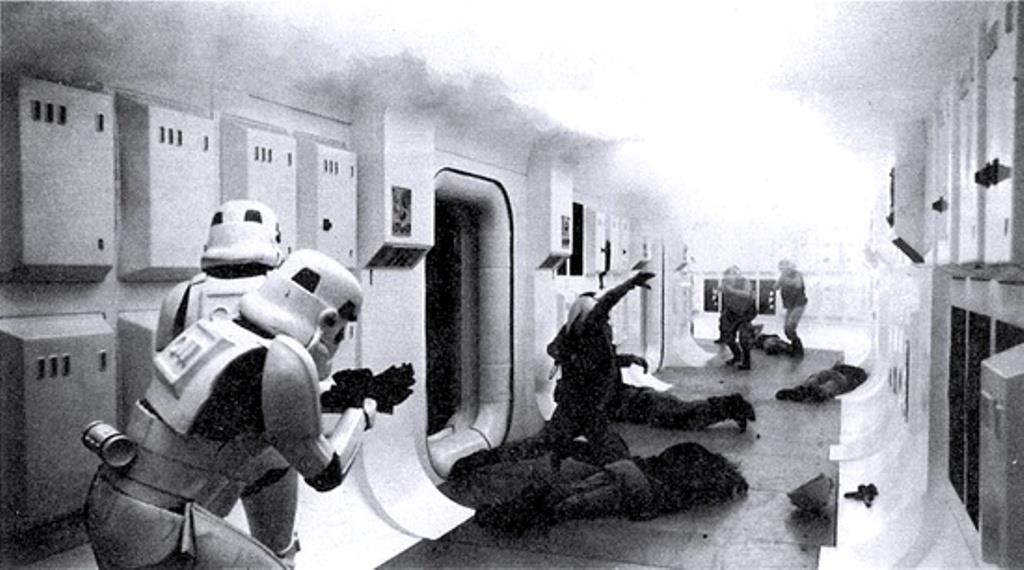

Promo pictures & others

- By Locitus,

- 0

- 35

-

Publicity Blaster - Nambu Type 99 LMG

- By gmrhodes13,

- 0

- 0

- 4

-

TFA F-11D Blasters

- By gmrhodes13,

- 0

- 0

- 13

-

Captain Phasma TFA References

- By gmrhodes13,

- 0

- 0

- 59

-

.jpg.da3b75dcced28b94590e16b06907ce49.jpg.d3465bdfa251d57f1217de22fbf5842f.jpg)